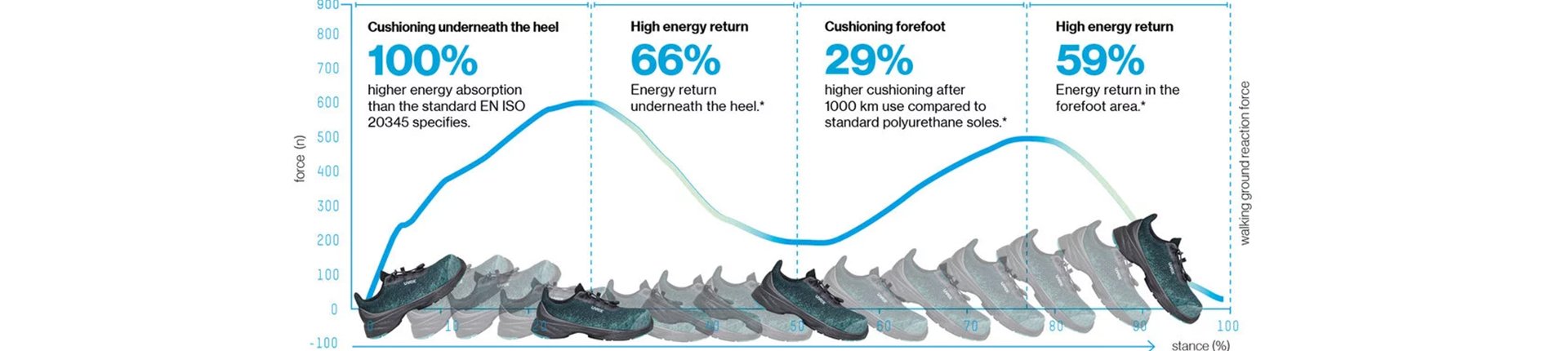

uvex i-PUREnrj technology

- Outstanding shock absorption properties at the forefoot and heel

- Excellent rebound energy over the entire midsole

- Foamed heel basket provides excellent stability and reduces the risk of injury

- uvex x-tended grip planet TPU outsole with up to 10% recycled PU waste from our production processes

uvex xenova® toe cap

- 100% metal-free

- Compact design

- Anatomical shape

- No thermal conductivity

- TPU scuff cap made from 40% recycled polymers, protects the upper for longevity

Penetration-resistant midsole

- Metal-free, penetration-resistant midsole made from 100% recycled material

- Removable antistatic comfort insole made from 100% recycled PET bottles and foam consisting of recycled PU production waste and recycled PU

- Does not restrict the flexibility of the shoe

uvex x-dry knit

- Virtually seam-free construction to eliminate pressure points

- uvex x-dry knit planet material made from 100% recycled PET bottles

- Breathable lining made from 18% bamboo and 52% recycled polyester

Midsole innovation: i-PUREnrj planet

uvex is the first company to have succeeded in using the direct injection process to integrate granulate made using polyurethane waste from production processes into the midsole of a safety shoe, and then to launch the fully-certified product on the market. This allows us to utilise less raw materials and to return PU waste to the shoe production cycle, without compromising the performance of our i-PUREnrj technology, which provides cushioning and energy return across the entire sole of the foot, helping reduce wearer fatigue.

The production in Italy, which is one of the most modern production facilities for safety shoes in Europe, ensures efficient, resource-saving production and short distances from manufacturer to user.

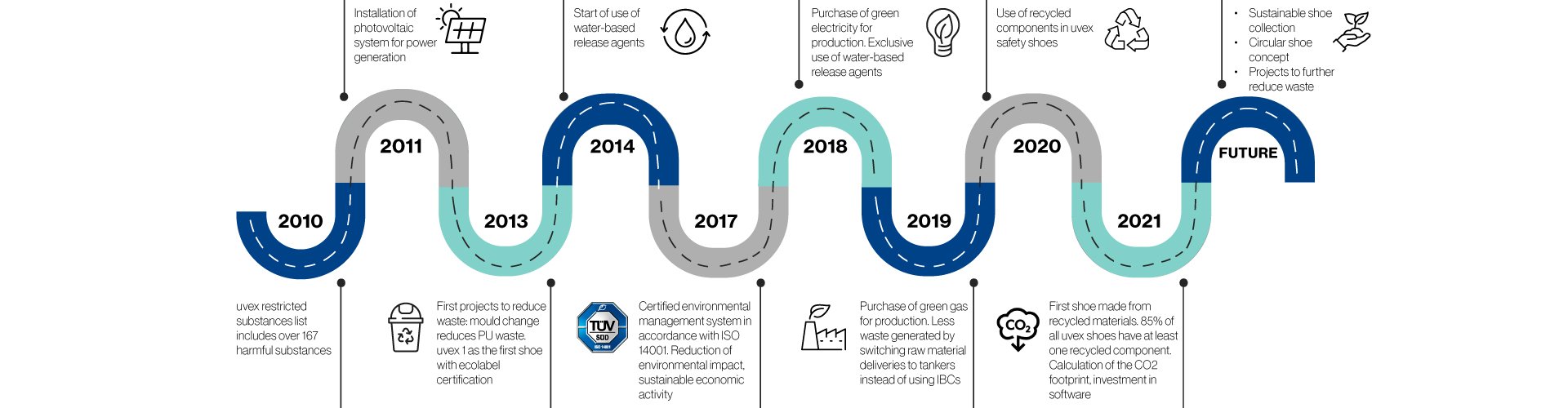

Sustainability at uvex footwear

uvex competence center for safety footwear in Ceva, Italy

Development expertise, state-of-the-art robot-controlled production systems and optimised process structures to meet the highest ecological standards guarantee the first-class and sustainable quality of our safety shoes.

The production in Italy, which is one of the most modern production facilities for safety shoes in Europe, ensures efficient, resource-saving production and short distances from manufacturer to user.

- Production of direct-injected safety shoes with outsoles made of polyurethane, thermoplastic polyurethane and rubber

- Innovative production technologies, e.g. for using rebound properties

- Four DESMA direct-injection machines for producing uvex outsoles, three of them with DESMA AMIR system (automated material handling with integrated robots)

- Extensively equipped test laboratory for quality and production assurance and for product development

Step 1

Removing the PU waste from the finished shoe

Step 2

Reducing the surplus PU production waste to granulate

Step 3

Absorbing and mixing the granulate into the PU compound

Step 4

Direct injection soling using PU material including granulate